The business world moves at breakneck speed. With in the world of automation, the goal is to create a system where the business can implement streamlined operations. To create a system where the focus is on the end product of the business or service, the implementation of a packaging machine is essential. Automation has created business in a way that product delivery has become so much more reliable. The businesses end goal is to be able to provide a product to a customer, packaging machines improve speed and consistency in a variety of ways.

Packaging Machines, The Basics

A packaging machine is built to cover a variety of functions that a business may have. They can fill, seal, wrap, and even place labels on products that need to be packaged. A packaging machine may be fully automated or may require semi manual operation. A packaging machine can do so much more than just contain a product. Other than that they ensure that a product is reliable and intact, they can improve the legitimize the of a product by create a new time line, provide a lost of the business's legal documents (through a coding system) and even improve a companies brand. These items can reduce the amount of staff a business needs and eliminate human mistakes.

Just like all other equipment, the evolution of packaging machinery has advanced alongside the growth of industrialization. From basic hand powered equipment to state-of-the-art machinery with the latest technological advancements in AI (artificial intelligence) and other environmental sensors, packaging equipment has updated to meet efficiency demands. The latest packaging machinery has the most state-of-the-art technology including AI, environmental sensors, touch screen interfaces, and other programmable logic controllers (PLC) to provide the most effective and accurate packaging solutions.

The Working Principle Behind Packaging Automation Systems

In order to understand how packaging machinery functions, we must look at the basic processes of how raw materials get converted to packages that can be sold. Systems that automate packaging have a number of basic functions that are typically consistent in all packaging systems. These functions include product feeding, measuring/counting, portioning (which can include filling a container with a product or wrapping a product), and finally closing and applying seals or labels to the packaging.

The feeding of the packing systems introduces the product or materials at controlled rates. This can be achieved through the use of large industrial conveyor systems, which utilize vibratory feeders or robotic pick and place units to ensure a consistent product flow to avoid bottlenecks. This initial feeding phase directly determines the pace of the entire packaging process and has significant impact on the packaging process throughput.

Systems used for measuring and dispensing are the most precise components of packaging machines. When it comes to liquid, powder, granules, or even solid products, accurate dosing ensures that products are consistent, that company standards are met, and that customers are satisfied. Combining volumetric fillers, gravimetric weighers, counting systems, and level sensors offers a solution for filling each container with the correct amount. Newer technology offers the ability to adjust and verify weight in real-time, regardless of external conditions or alterations to the materials used.

Varied Types of Packaging Machinery Used in Industry

The number of packaging machinery available in the market today is extremely extensive, with a wide variety of machinery that is very specialized in function, based on the materials, type of containers, and rate of production. One of the largest categories of filling machines is designed distinctly to accommodate liquid products, powdery substances, granular materials, and viscous paste-like formulations. Packaging for liquid products can be as simple as gravity fillers, or as complex as piston fillers and pump systems for more viscous products.

Form-fill-seal machines are fully integrated solutions capable of producing uncontaminated bulk filled containers from roll stock film. These adaptable machines are equipped with a varied number of product fillers, lock and seal mechanisms, and are exceptionally versatile for the packaging of consumer snack foods and hardware items, as well as for the pharmaceuticals industry, and many other sectors. These machines can produce diverse bag types, such as pillow bags, gusseted bags, and quad-seal bags, as well as flow-wrap bags, which are often used for individual wrapped products like candy bars, baked products, and some medical products.

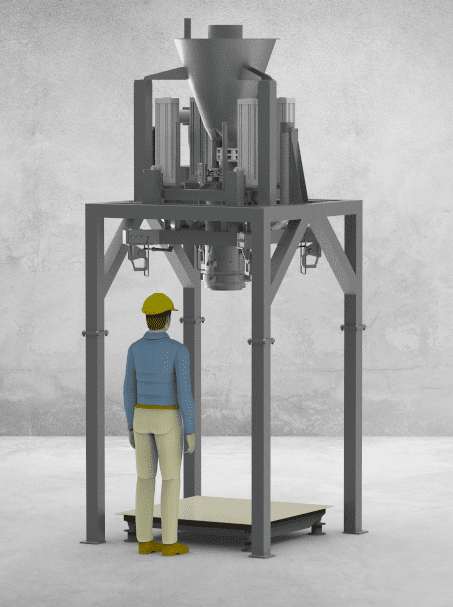

Specialized industry equipment is especially important when working with bulk materials. The Jumbo bag filling machine is built for high-efficiency mass packaging of chemicals, mined materials, certain agricultural products, and construction commodities on a bulk-industry level. These high-performance machines are built for the extreme functionality of handling bulk bags, known as super sacks or FIBCs (Flexible Intermediate Bulk Containers), which can hold between 500 and 4000 pounds. This type of equipment is used for weighing, dust collection, automated filling, and spout mechanisms to ensure a filled bag while improving the safety and health of a working environment. The industries of bulks material handling, such as mining, construction, chemical manufacturing, and agriculture, rely heavily on this type of high-capacity filling equipment to improve the quality of logistics and lower product handling costs.

Special Tools Needed for Different Materials

Different materials and container types impact the way the packaging industry operates and the kinds of machines that are necessary. In the case of top paper valve bag filling machines for example, these machines work for powdered products that need to be filled efficiently and securely contained. These machines are multi-wall systems that fill paper bags through specific valve openings that seal automatically once filling is done, so there is no separate sealing operation to worry about. Because of these systems, the cement, chemical, animal feed, food ingredients, and construction materials industries love them due to the control of dust and their packaging speed. Additionally, valve bags are wonderful because they provide moisture and contamination protection while also keeping certain products breathable. Filling These bags.

A range of different materials for containers and closure types are what causes spindle capping, chuck capping, snap capping, and even induction sealing of the top products. These types of sealing keep products uncontaminated and fresh for storage and distribution. Advanced sealing technology, like the use of adhesives, is also employed and all of these things give products a longer shelf life with a seal that is evident to prove that the seal is made.

Packaging machinery includes Stretch wrapping, over wrapping, bundling, mini wrapping, and mini bundling. Packaging and technology make it possible to create tight, transparent sealed packages that protect products from moisture, dust, and tampering while still being able to see the products. Stretch wrapping systems keep pallet loads stable to ensure safe transport and warehousing.

How Packaging Technology Helps EMI to Maintain Standards.

Newer techniques in packaging machinery help in attaining quality standards by using integrated inspection systems and monitoring the process. Automated quality checks happen at production speeds, so packaging systems do not slow down. With-monitoring systems ensure that products are not under or over filled.

Packages that are under or over filled will not reach the customers to maintain the companies reputation and stay within the guidelines and rules they are governed by. Software that uses statistical process control, looks at data and helps the company in preventing problems that will affect the quality of the product while packaging.

In the packaging of the pharmaceutical industry, food, and consumer goods, the importance of labelling for tracing products is becoming paramount. In the industry packaging lines of today, there are integrated systems that print and apply unique identifiers, barcodes, QR codes, and RFID tags to packaged items. These make possible complete visibility of the supply chain and record products, meet standards, and make recalls easy.

Choosing a packaging solution

Finding the correct packaging apparatus is a complex operation because it involves many variables. The main variable is the quantity of production. If it is low, a manual or semi-automatic machine is perhaps sufficient, but for high production steps a fully automated continuous-motion system is mandatory. If low, a manual or semi-automatic machine is perhaps sufficient, but for high production steps a fully automated continuous-motion system is mandatory.

The type of product is another. If it is, for example, very viscous, fragile, or very cold, it requires a certain type of technology. If the product is very reactive, there are also factors to consider. A packaging machines manufacturer usually has a lot of information about the compatible systems, and most of them will even run a test of any product before selling the machine.

When it comes to containers, the size, shape, material, and type of closure narrows down the selection of machines. While some machines can accommodate a broad range of containers with easy changeover, others are designed for specific types of containers. When it comes to flexibility and the efficiency trade-off of specialized equipment, highly flexible basic machines tend to have a low speed and precision compared to dedicated machinery.

Tips for Harmonizing Packaging Lines

Building efficient packaging lines involves more than picking good individual machines. It requires good harmonization of separate systems into a cohesive production line. Analyzing the flow of materials can help in determining the best location for equipment, minimizing the amount of handling of the product, and eliminating bottlenecks. The speed of conveyor systems, distance to packaging stations, and the rate of packaging must be balanced in order to achieve a steady flow.

Integration of a control system provides the ability to centrally monitor and control a number of machines using programmable logic controllers and supervisory control and data acquisition (SCADA) systems. The combination of unified interfaces reduces the complexity of training for the operator, allows for the optimization of the process, and provides data on the production. The combination of systems and the use of the Internet of Things (IoT) can also be used to monitor systems, plan repairs, and analyze data over the Internet.

Changeover efficiency and overall equipment effectiveness are two things in a facility that produces multiple items and package formats. Minimal downtime occurs when quick change tools are adjusted. Features for changeover include automated backup, fast changeover tools, recipe recall, and modular systems. Changeover capabilities are equipment that pays dividends in a facility with a frequent diversity of product portfolios or format changes.

Breakthrough Technologies in Packaging Automation

Artificial intelligence and robotics are revolutionizing the packaging process. Packaging operations can now integrate collaborative robotics to provide safe, repetitive, and close processing. Artificial intelligence can learn and improve systems that analyze defects, remove unique anomalies, and provide superior primary quality. Predictive analytics systems operate before breakdowns to provide task and reduce the risk of costly downtime.

New packaging designs that are incorporated with compostable, recyclable, and biodegradable materials are packaging sustainably. These materials include different handlings that are free of traditional packaging plastics. Right-sizing systems are hinges that provide the balance of protection, minimizing materials, and providing superior quality of the the product by adjustable the packaging. cosmetic, alcoholic, and liquid materials are optimized to improve efficiency that reduce cost and provide less environmental impact.

Potential changes to market and customer preferences can be addressed with the principles of flexible manufacturing. When modular equipment design is used, the ability to expand capacity is accomplished by adding additional parallel processing stations instead of having to replace whole systems. With the aid of digital twin technology, virtual replicas of packaging lines can be built to simulate, optimize, and even train operators, all without necessitating disruptions to production. With augmented reality maintenance tools, technicians can be led through repair processes which can be used to curb downtime and to expand repair the cadre of technicians who can perform the necessary repairs.

Maintenance Strategies for Maximum Equipment Longevity and Performance

To keep packaging equipment investments safe and make sure everything is working as it should, comprehensive maintenance should be applied. Fall preventative maintenance is based on the manufacturers recommendations and consists of regular inspection, cleaning, and replacement parts to make sure there are no stitching failures. Maintenance activities should be documented for the purpose of tracking the history of maintenance work and for future decision making, as well as spotting recurring issues that might need to be worked on by engineering.

Predictive Maintenance is based on the use of sensors and analytics; the best timing for servicing is determined based on the actual state of the equipment rather than based on time, production cycles, or part counts. Using vibration analysis, it is possible to detect the presence of worn bearings, problems with alignment, and mechanical imbalances that can occur prior to catastrophes. Electrical imbalances and problems, bearing friction, and the deterioration of seals can be detected through the use of thermal imaging. System lubrication breakdown, as well as component wear, can be detected by oil analysis and systems pneumatic and hydraulic.

Investment in training is an important, if often overlooked, part of maintenance. Well-trained operators can identify issues like unusual sounds, temperatures, and operational performance. They’re able to do changeovers to prevent damage, make adjustments to keep performance optimal and communicate with maintenance staff about any changes with the equipment. Thorough training provides benefits like less downtime, better quality, and longer lifespans of the equipment.

Economic Factors in Investing in Packaging Equipment

When analyzing packaging machinery, one must go beyond just the purchase price to include an analysis of the equipment’s total cost of ownership. Most operational costs, like energy, disposables, and labor, have an immediate impact on profitability. It is not uncommon for equipment with higher purchase prices to result in a cheaper total cost of ownership. This is often because high efficiency machinery have lower operational costs.

Increased throughput means more sales and that justifies the investment. It also means that with the new automated line, labor can be moved from mundane manual tasks, like those that involve a lot of repetition, to more important tasks after the line, like quality check, process improvement, and monitoring the equipment. Consistency creates less waste and less rework, increases customer satisfaction, and increases margins. The ability to be flexible to changing demands is what stands out during tough and flexible market conditions where companies modify their product mix, package formats, and production volumes. Systems and equipment optimized to meet diverse production requirements without extensive reconfiguration keep productivity during transitions that would stall less flexible systems. This productivity stands out in an increasingly growing market as successful manufacturers outpace their competitors who cannot adapt to the current market needs.

Industry Standards and Regulatory Compliance in Packaging Systems

Leading manufacturer of packaging machine face industry standards and regulations that differ in scope, detail, and focus based on product type, market geography, and application. Packaging systems in food processing facilities require adherence to sanitary design principles that mitigate the risk of microbial contamination and support the cleaning and unhindered practice of cleaning. Equipment design that is hygienically certified for food contact applications provides stainless steel construction, tool-free disassembly, self-draining design, and sealed bearing assemblies.

In addition to the general industry regulations, the packaging of pharmaceuticals is subject to more stringent requirements, including the current Good Manufacturing Practices (cGMP). These regulations incorporate extensive documentation, validation, and a quality management system. This means that manufacturers must provide records relating to the design, materials, construction, performance, and qualification of the system, including the necessary components to support validation. Packaging systems must be able to apply a unique identifier to each prescription medication and keep a record of the production process to comply with the regulations of pharmaceutical packaging. Machinery safety standards prevent injuries related to ergonomics, mechanics, and electronics during packaging processes. The practice of machine guarding provides access to parts of a machine that is vital for modifications and during running cycles. When emergency-stop actions are implemented, the machine should stop running, and mechanisms must prevent a machine from restarting automatically. The reducing activities of a packaging process safety standards are designed to keep both the employees and employers free from accidents and the consequences of a safety violation.

The constant evolution of the packaging machine industry is caused by technological, market, and social changes. Knowing the distinct functions of advanced systems, manufacturers can confidently enhance competitiveness and improve operations. Whether a packaging line is being introduced for the first time or existing operations are being upgraded, meticulous planning and the right expertise will provide a successful result that will create a positive contribution over a prolonged period.